Microducts for Fiber Delivery

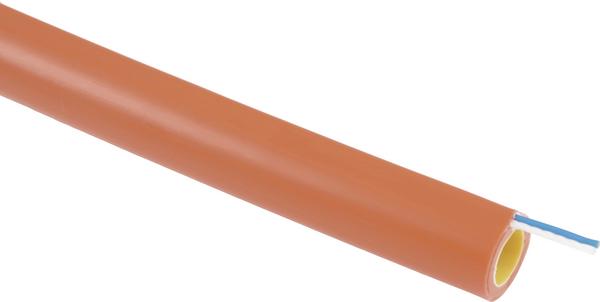

FieldShield® starts with a ruggedized microduct designed to support all aerial, direct bury, and inside plant “last mile” needs. Created from the most rugged HDPE polymers, FieldShield Microduct is strong enough to be placed using traditional methods of boring and plowing, allowing you to leverage your existing conduit placement equipment.

Clearfield's FieldShield Microducts

FieldShield® starts with a ruggedized microduct designed to support all aerial, direct bury, and inside plant “last mile” needs. Created from the most rugged HDPE polymers, FieldShield Microduct is strong enough to be placed using traditional methods of boring and plowing, allowing you to leverage your existing conduit placement equipment. Using our small form factor fiber duct system also enables you to take advantage of less disruptive technologies such as micro trenching or saw cutting.

What’s more, due to its high column strength, FieldShield Microducts can be deployed as a rod directly within a larger occupied duct that was previously thought exhausted. The lack of space and the costs associated with constructing new pathways through the riser space can be just as prohibitive as digging up city streets.

FieldShield Microducts provide a fiber delivery pathway to quickly deliver pre-terminated, factory-tested pushable and pullable FieldShield Fiber. Duct options address aerial and buried environments in the OSP, as well as plenum and riser configurations in the ISP. Utilizing same port connectivity technology for last mile drop applications, microduct, mated with a FieldShield FlexConnector allows for plug-and-play connectivity between the YOURx-Terminal – no matter which type of drop cable is desired.

Additional FieldShield Accessories are also available to help install and complete a fiber duct project.

How Can We Help?

It's important to Clearfield that we LISTEN and understand the needs you have for your fiber network. We’d be honored to put our industry experts to work to help you achieve your goals.